|

|

- vbeltworld.com is all about Industrial V-Belt, Auto Belt, Raw Edge Cogg Belt, Fan Belt, Timing Belt, Harvestor Combine Belt, Timing Belt, Variable Belt, Poly Belt,

- Wedge Belt, Narrow Belt, Hexagonal Belt & other belt.

|

V-belts (also known as Vee Belt) are used for Power Transmission. It is like roller chain or other tools that generally used

for power transmission in machines. It has solved the slippage....

Read More >>

|

|

About V-Belts

V-belts (also known as Vee Belt) are used for Power Transmission. It is like roller chain or other tools that generally used for power transmission in machines. It has solved the slippage and alignment problem. It provides the best combination of traction, speed of movement, load of the bearings, and long service life. As per available information V-belt was developed in 1917 by John Gates. V-Belts are endless, and on installation it takes a V-Shape. V-Belts are installed on V-Belt Pulleys or sheave. With time huge development has taken place in V-Belts also. Basic Raw Materials for V-Belts are Rubber, Polyester Cord & Fabric.

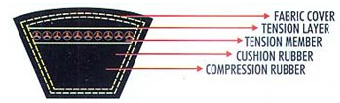

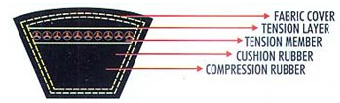

Rubber both the natural rubber and various types of synthetics rubber after due treatment with rubber chemicals is used to form the Cushion and Compression and Cord is used to form the Tension Layer and everything is intact together using the Fabric Cover to form the V-Belt.

Rubber both the natural rubber and various types of synthetics rubber after due treatment with rubber chemicals is used to form the Cushion and Compression and Cord is used to form the Tension Layer and everything is intact together using the Fabric Cover to form the V-Belt.

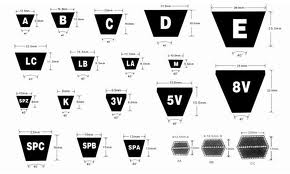

To fully specify a belt, the material, length, and cross-section size and shape are required. Timing belts, in addition, require that the size of the teeth be given. Dimensions of Vee Belt include Outside Length, Inside Length and the angle. Depending on power requirement, space limitation, friction, temperature and nature of industry many types of Vee Belts has been developed. Various types of V-Belts available in market today include Classical Belts, Fractional Horse Power Belts, Space Saver Wedge Belts, Narrow Belts, Raw Edge Belts, Poly Belts, Flat Belts, Harvester Combine Belts, Banded Belts, Timing Belts.

Each type of Belts has own application. In addition to the above Length is another important factor that decides a complete V-Belts. And because of this variation V-Belt exists in huge range. And this creates a great challenge for the Manufacture, Distributor, Dealers to maintain the inventory of V-Belt. The Business of V-belt definitely need a big investment.

- Ajanta Belts Pvt Ltd

(Karnal)

- Amber Engineering

(Rajkot)

- Bhatia Mill Store

(Ludhiana)

- Bharat Mill store

(kichha)

- Cheema Agro Corporation

(Rudarpur)

- Forech India Ltd

(New Delhi)

- Mahalaxmi Textile parts

(Panipat)

- Jagruti Rubber Pvt Ltd (Ahmedabad)

- Mercury Rubber Mills (Delhi)

- Navyug (India) Ltd (Jalandhar)

- Neelkanth Beltings (Jalandhar)

- NRC Industries Ltd (Amritsar)

- Omfa Rubbers Pvt Ltd (Noida)

- Pix Transmission Ltd (Nagpur)

- M/s Shakti Cords Pvt. Ltd. (Chennai)

- M/s G.D. Textiles Pvt. Ltd. (Chennai)

- M/s Orient Polyfilms Pvt. Ltd. (New Delhi)

- M/s Tirupati Chemicals (Meerut)

- M/s Rajshila Synthetics Pvt. Ltd. (Delhi)

- M/s Singh Plasticiers & Resins (New Delhi)

- M/s Thakar Dass & Co. (New Delhi)

Save Energy, Replace V-Belts with Cogged or Synchronous Belt Drives

About one-third of the electric motors in the industrial and commercial sectors use belt drives. Belt drives provide flexibility in the positioning of the motor relative to the load. Pulleys (sheaves) of varying diameters allow the speed of the driven equipment to be increased or ...

Read More >>

|

Save Energy, Replace V-Belts with Cogged or Synchronous Belt Drives

About one-third of the electric motors in the industrial and commercial sectors use belt drives. Belt drives provide flexibility in the positioning of the motor relative to the load. Pulleys (sheaves) of varying diameters allow the speed of the driven equipment to be increased or decreased. A properly designed belt transmission system provides high efficiency, decreases noise, requires no lubrication, and presents low maintenance requirements. However, certain types of belts are more efficient than others, offering potential energy cost savings.

The majority of belt drives use V-belts. V-belts use a trapezoidal cross section to create a wedging action on the pulleys to increase friction and improve the belts power transfer capability. Joined or multiple belts are specified for heavy loads. V-belt drives can have a peak efficiency of 95% to 98% at the time of installation. Efficiency is also dependent on pulley size, driven torque, under or over-belting, and V-belt design and construction. Efficiency deteriorates by as much as 5% (to a nominal efficiency of 93%) over time if slippage occurs because the belt is not periodically re-tensioned.

Cogged belts have slots that run perpendicular to the belts length. The slots reduce the bending resistance of the belt. Cogged belts can be used with the same pulleys as equivalently rated V-belts. They run cooler, last longer, and have an efficiency that is about 2% higher than that of standard V-belts.

Synchronous belts (also called timing, positive-drive, or high-torque drive belts) are toothed and require the installation of mating toothed-drive sprockets. Synchronous belts offer an efficiency of about 98% and maintain that efficiency over a wide load range. In contrast, V-belts have a sharp reduction in efficiency at high torque due to increasing slippage. Synchronous belts require less maintenance and retensioning, operate in wet and oily environments, and run slip-free. But, synchronous belts are noisy, unsuitable for shock loads, and transfer vibrations.

|

Computer Assembling, Branded Computers, Laptops, Upgrading Repairing, Troubleshooting, A.M.C,

Networking Solution LAN/WAN, Software & Hardware Installations.

Address : G-103, Kalkaji, New Delhi 110019,

Ph : 011- 40553710, 26439761

Mobile : 9811289154

Email : keltroncomputers@hotmail.com

|

|

|

Rubber both the natural rubber and various types of synthetics rubber after due treatment with rubber chemicals is used to form the Cushion and Compression and Cord is used to form the Tension Layer and everything is intact together using the Fabric Cover to form the V-Belt.

Rubber both the natural rubber and various types of synthetics rubber after due treatment with rubber chemicals is used to form the Cushion and Compression and Cord is used to form the Tension Layer and everything is intact together using the Fabric Cover to form the V-Belt.

Blog Archive

Vocabulary Term

& Descriptions

Machine Used In

V-belt Manufacturing

Right Time to

replace the V-belt

D & D Power Drive

belt

What is v-belt